Quality craftsmanship, creating exquisite products

Taizhou Wanshun Precision Machinery Co., Ltd.

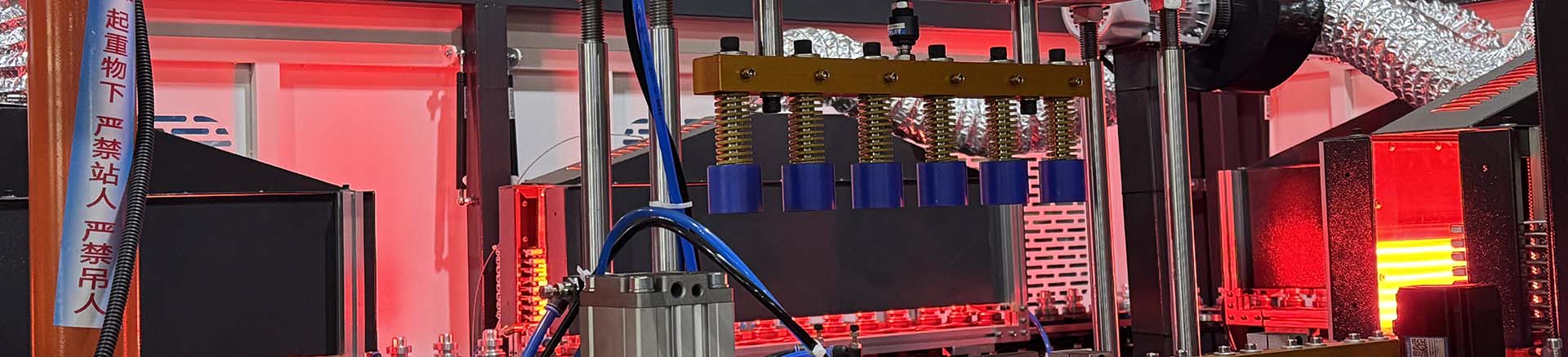

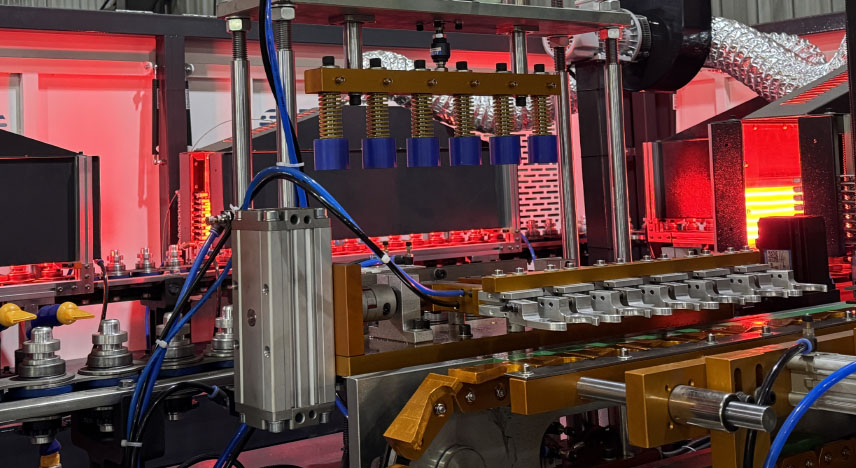

Wanshun Machinery, rooted in Huangyan, Taizhou, Zhejiang, China's "Mold Town," is a high-tech enterprise specializing in the research and development, manufacturing, sales, and service of high-end intelligent blow molding machines. Since its establishment in 2016, leveraging Huangyan's rich mold industry heritage and intelligent manufacturing expertise, we have been committed to providing stable, efficient, and energy-saving blow molding solutions to customers worldwide.

As a hub for China's plastic mold industry, we enjoy unparalleled industry advantages and a deep pool of technical talent. Drawing on this fertile ground for innovation, Wanshun Machinery deeply integrates sophisticated mold craftsmanship, innovative mechanical design, and digital intelligent technologies to ensure that every piece of equipment we produce is built with high precision, durability, and exceptional production efficiency.

As a hub for China's plastic mold industry, we enjoy unparalleled industry advantages and a deep pool of technical talent. Drawing on this fertile ground for innovation, Wanshun Machinery deeply integrates sophisticated mold craftsmanship, innovative mechanical design, and digital intelligent technologies to ensure that every piece of equipment we produce is built with high precision, durability, and exceptional production efficiency.

0

Honors

Certificate

0

Experienced

workers

0

%

Customers

Satisfied

0

+

Completed

Project